Food Products Case Study – Candy Manufacturer

A major Candy Manufacturer had an opportunity to increase sales from their Bulk-box hard candy line to a large-lot retailer. Coupled with their existing restaurant and institutional 30 pound case sales, they saw this contract as an opportune time to automate their bulk box line. With about 30 people retiring, they hoped to shrink their packaging workforce from fourteen per shift down to five. Scheme & Equipment, Inc. (SEI) used stainless steel troughed bulk belt conveyors to bring four different candy lines to a centralized packaging area on the fourth floor, accumulate the cellophane-wrapped candy and meter it into four separate scale systems.

A major Candy Manufacturer had an opportunity to increase sales from their Bulk-box hard candy line to a large-lot retailer. Coupled with their existing restaurant and institutional 30 pound case sales, they saw this contract as an opportune time to automate their bulk box line. With about 30 people retiring, they hoped to shrink their packaging workforce from fourteen per shift down to five. Scheme & Equipment, Inc. (SEI) used stainless steel troughed bulk belt conveyors to bring four different candy lines to a centralized packaging area on the fourth floor, accumulate the cellophane-wrapped candy and meter it into four separate scale systems.

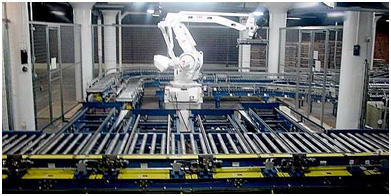

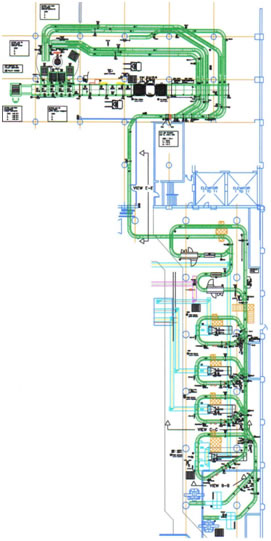

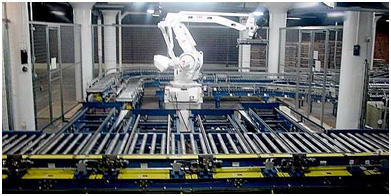

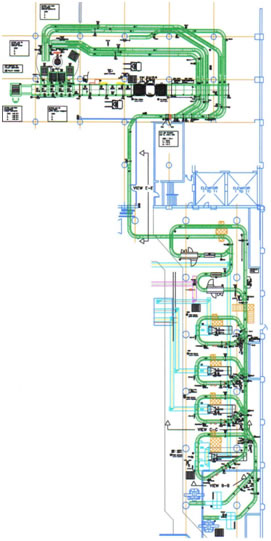

Meanwhile, the case handling system began with case erectors and bag inserters, after which the conveyed empty cases responded to automatic calls from the four delivery loops under the scales. After filling, the cases were discretely marked for which scale they had been filled from, followed by labeling and a tamp-down process (relaxed cellophane twists do not allow a case to settle with vibration). A common line then brought all cases to a bag uncuffer and case sealer. Cases were then conveyed to another building where they were sorted back out into four separate candy lines by reading the discrete scale-line mark, followed by delivery to the work envelope of a robot palletizer. On the opposite side of the robot palletizer, a pallet dispenser supplied empty pallets to four pallet-building stations via conveyor. This same conveyor was a common full-pallet removal line with pallet labeling, stretch wrapping, and accumulation for removal via elevators to a first floor shipping area. Eventually, the customer determined that three operators could run the entire system. SEI did the layout work, supplied packaging and conveying equipment, performed system integration with controls and programming, then did the implementation with mechanical installation and field wiring.

|

|

Scale Loops |

Robot Palletizer (Four in, Four out) |

|

|

|

Fill Station with Vibratory Scale above it.

A candy Accumulator feeds the Scale.

The Conveyor Loop provides empty cases and takes away full cases.

|

Reject Line (Foreground).

Robot Palletizer (Background).

|

|

|

|

Declines from another building feed the Palletizer. |

Pallet Dispenser & Robot Palletizer |

|

|

|

Bulk Candy Accumulators elevating to scales

(Shown in Stainless Steel).

Case Conveyors (Shown in Blue).

|

Case Erectors

|

|

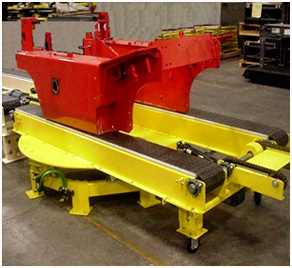

Automotive Products Case Study – Forklift Manufacturer

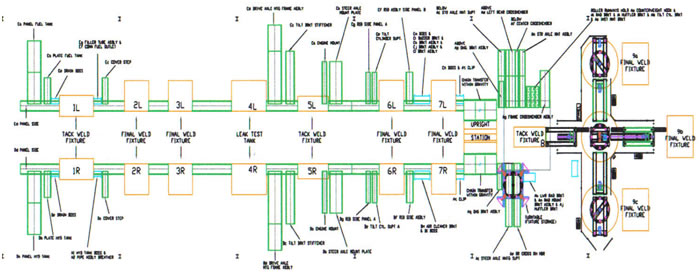

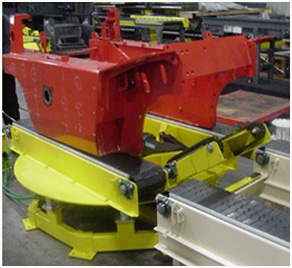

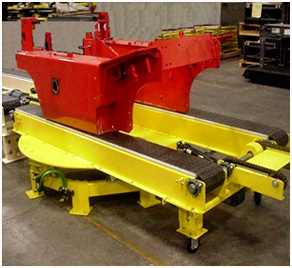

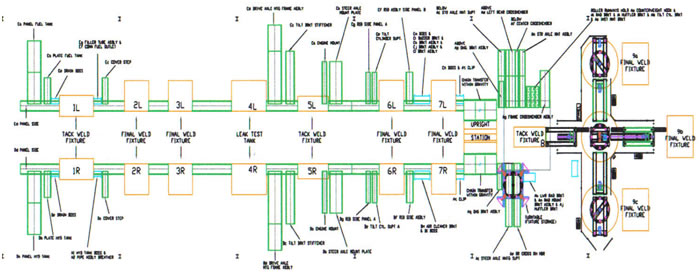

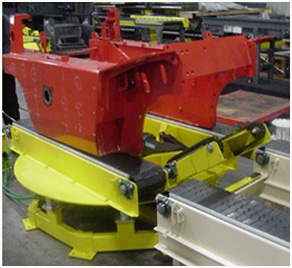

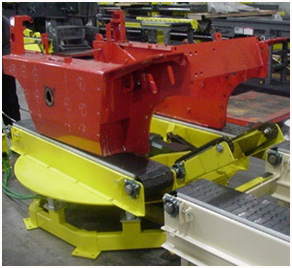

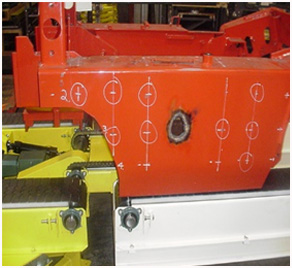

A major Forklift Manufacturer had an unusual conveying need; their forklift welding line had to be able to easily transport forklift bodies from station to station during the welding process. The weldment got heavier and harder to handle as the process continued. SEI solved this problem with several standard approaches and some unique ones as well. Each side of the forklift body is moved forward from left to right in the drawing shown (with the left body-half on the top line, the right body-half on the bottom line). Welding stations are brown, and roller conveyors are green. These conveyors are heavy duty gravity roller units up until a pop-up chain transfer after station(s) 7. The transfers pull each body-half weldment into the middle so they can be rough-welded to each other at station 8, about a five minute process. Since the operator needs to have access to move around the entire weldment, a Transfer car stands away to the right while this is done. When the rough-weld is completed, the T-car moves in and loads the weldment using a steel tabletop conveyor surface (a buss means the underside of the product is not firm and flat, so rollers would not work). Because station(s) 9 are actually three finish weld stations taking about 15 minutes each, a turntable with tabletop chain conveyor surface needs to deliver up on the page to 9A, straight ahead to 9B, or down on the page to 9C. The weldment goes up or down to 9A or 9C via a transit conveyor and then turns on another turntable. Alternatively, the weldment goes straight ahead to 9B using another Transfer car. That 9B Transfer car moves away during welding. The 9A and 9C turntables are actually cantilevered to rotate out of the operators way for welding.

|

|

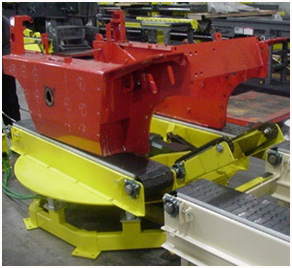

A Transfer Car in position to feed the Central Turntable. |

The Central Turntable can feed all three Finish Weld stations. |

|

|

|

There are two Cantilevered Swing-Away Turntables so Welders can access the product.

|

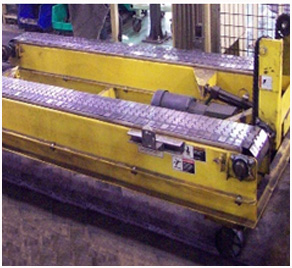

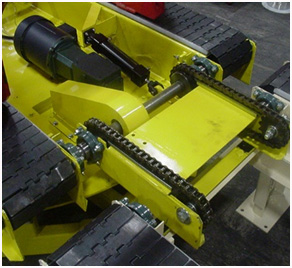

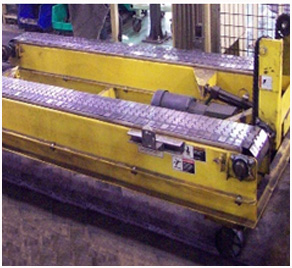

The unusual Transfer Cars Feature two strands of Steel Belting

|

|

|

|

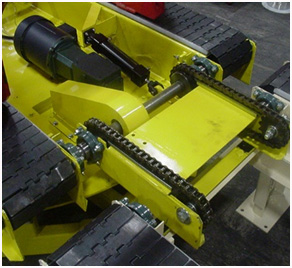

Special Swing-Down Transfer Chains are used to bridge gaps. |

Transfer Chains Swing into Position. |

|

|

|

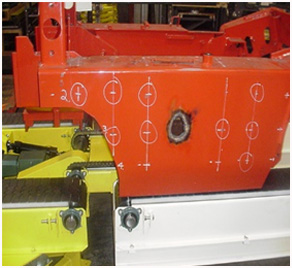

A Transfer in Process (going from Left to Right).

|

This Transfer Car moves using a Pneumatic Cylinder Mounted in Position along the floor.

|

|

A major Candy Manufacturer had an opportunity to increase sales from their Bulk-box hard candy line to a large-lot retailer. Coupled with their existing restaurant and institutional 30 pound case sales, they saw this contract as an opportune time to automate their bulk box line. With about 30 people retiring, they hoped to shrink their packaging workforce from fourteen per shift down to five. Scheme & Equipment, Inc. (SEI) used stainless steel troughed bulk belt conveyors to bring four different candy lines to a centralized packaging area on the fourth floor, accumulate the cellophane-wrapped candy and meter it into four separate scale systems.

A major Candy Manufacturer had an opportunity to increase sales from their Bulk-box hard candy line to a large-lot retailer. Coupled with their existing restaurant and institutional 30 pound case sales, they saw this contract as an opportune time to automate their bulk box line. With about 30 people retiring, they hoped to shrink their packaging workforce from fourteen per shift down to five. Scheme & Equipment, Inc. (SEI) used stainless steel troughed bulk belt conveyors to bring four different candy lines to a centralized packaging area on the fourth floor, accumulate the cellophane-wrapped candy and meter it into four separate scale systems.